Calibration

Calibration is the process of adjusting an instrument so that it provides accurate readings. While this may seem like a tedious and time-consuming task, calibration is actually essential for ensuring the accuracy of measurements. In many industries, such as manufacturing and healthcare, even a small error can have serious consequences. By calibrating instruments on a regular basis, businesses can avoid costly mistakes and ensure that their products meet the highest standards. In addition, calibration can also help to prolong the life of an instrument by preventing wear and tear caused by incorrect readings. As a result, regular calibration is a critical part of maintaining accurate measurements.

Repair

To minimize delay and costs, Armour Scale Company’s factory trained and qualified personnel will diagnose inaccurate and broken scales.

Certification

Any business that “sells across” the scale, or uses the scale to determine a price for the acquisition or sale of commodities, must obtain scale certification in order to operate legally. Scales that have been certified make it easier to verify that the weight indicated on the scale’s weight indicator accurately represents the weight of the goods. A flawed or inaccurate scale may cause the buyer to pay for more products than they actually received, or it may cause the buyer to charge less than the product was actually worth. Armour Scale company, a state-licensed service provider, must be able to show that the scale generates precise measurements. State-licensed service providers test scales using NIST traceable certified test weights to certify them as scales.

Cleaning

The scale deck and any moving parts can be swiftly worn out by dirt, pebbles, and other debris since they are abrasive. Scale movement may be impeded by debris between weigh modules, the end wall, and the ground. Your truck scale will weigh incorrectly as a result of this restriction. Debris will trap additional moisture under your scale if it is not removed. This additional moisture promotes condensation, freezing, and corrosion. Our staff employs specialized cleaning techniques to drain out all extra material without endangering the delicate weighing apparatus. If your scale has accumulated debris, we can design a solution to maintain and keep it operating properly and weighing precisely.

Maintenance

To maximize a scale’s life, performance, and accuracy while minimizing downtime, preventative maintenance is crucial. The volume of the product being weighed should be taken into account when developing a preventative maintenance schedule, but as a general rule, at least two maintenance sessions should be performed annually. Before problems arise, we inspect the scales to find any potential problem spots, check the scale’s accuracy by using it, correct any tolerance problems by calibrating the scale, and show thorough test results and certifications. The National Institute of Standards and Technology’s testing and calibration regulations are rigorously adhered to by Armour Scale Company (NIST Handbook-44).

CT109 (California Test 109)

At all facilities that manufacture materials for CalTrans projects, such as rock, sand, gravel, and concrete, Armour Scale Company can conduct a test known as CT109 (California Test 109) in conjunction with a CalTrans Weights & Measures Engineer. This test is done to ensure that all weighing and measuring equipment is operating following the rules set forth by the California Division of Occupational Safety and Health, the U.S. Department of Labor’s Occupational Safety and Health Administration, and the California Department of Transportation.

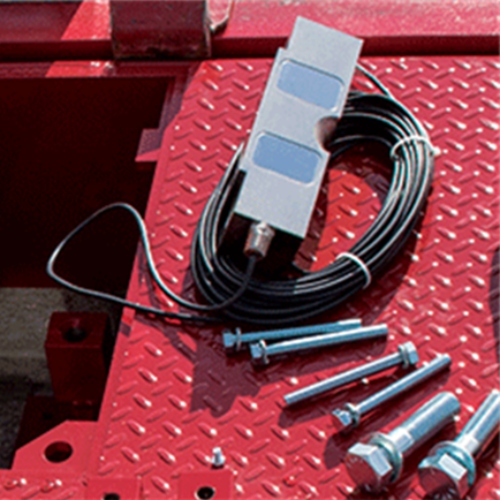

Parts and Scale Sales

We offer a broad selection of high-quality weighing products made for all applications in a variety of sectors.